Shrinkage is a formidable foe in the cutthroat retail and supply chain management arena. It is the phantom-in-the-machine, the leakage of profitability. The conservative approaches to inventory, such as manual counts and barcode scanning, are like taking a flashlight to a shadow search: very slow, subject to error, and only give temporary views of reality.

Introduce RFID (Radio-Frequency Identification), the automated inventory technology that not only eases operations, but is also becoming a strong, 24/7 watchdog against loss. This is the way RFID automated inventory is becoming the ultimate weapon in shrinkage reduction.

What is shrinkage?

Shrinkage takes into account every loss of inventory between manufacturing and sales. Its primary culprits are:

- Theft: External (shoplifting) and internal (employee theft).

- Misadministrative: Scanning oversights, manual errors, and pricing errors.

- Supplier Fraud: Under shipment or unscanned.

- Unknown Loss: It is the inventory that is lost without any trace, and in many cases, the process fails.

The conventional systems fail to identify the when, where, and how of such losses and leave the business at fault.

How to use RFID in the best possible way for precise results?

RFID makes use of miniature radio signal transmitters. Contrary to barcodes that need line of sight, RFID readers can scan hundreds of objects within a few seconds in a box, crowded rack, or even a warehouse door. This capability jump goes directly to the shrinkage source.

Inventory management with accuracy

Inventory in format of a manual is disruptive and infrequent (usually quarterly or annually). RFID allows doing cycle counts either daily or even in real-time with very little work.

It is always better to first tag high-value or high-shrinkage items. The short-term data ROI will create the justification to expand the rollout.

Inefficiencies are identified in hours and not in months. Such a quick identification eliminates the possibility of repeat theft and allows one to investigate the activity of a particular day quickly.

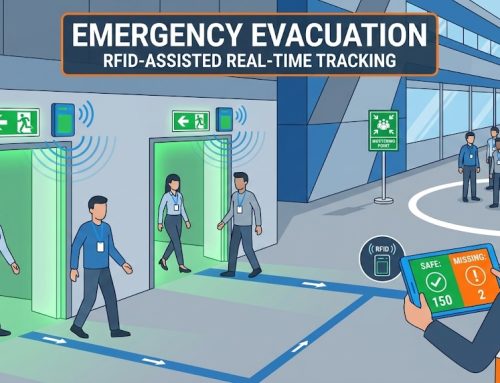

Real-time visibility

RFID changes your inventory into a living, breathing map of your assets.

At the Store Door

RFID readers will be able to be the electronic article surveillance (EAS) on steroids and record what was paid and when, while identifying what was not paid.

Backroom and Sales Floor

Be able to know whether or not a batch of high-value items was transferred out of the secure stockroom to the floor and whether or not it was sold. Suspicious activities, such as ten smartphones going to a non-public place, could issue alerts.

Tip: Incorporate the RFID reader data with a security camera system in your store. A tag removal alert can trigger a video of the time and aisle, and this would be invaluable evidence.

Finding the root cause

RFID data is forensic. You can see: not merely that you are missing 15 pairs of jeans, but:

They were stolen between 2 PM and 4 PM.

They were last seen in Aisle 3.

At the entrance of the fitting room, their tags were disabled or surrounded.

This accuracy brings the discussion out of We have a problem and into We have a definite and solvable incident.

Possibility of eliminating error

A large part of the shrinkage is administrative. RFID streamlines the receiving, picking, and transfer:

Receiving

Within seconds, a complete pallet can be compared with the purchase order, and supplier mistakes can be detected immediately.

Transfers

Make sure that what is shipped out of the warehouse is what was received by the store, and that this will remove inter-facility loss.

Hint

RFID can be used to enable employees. Mobile RFID readers are used to speed up the staff in finding items to serve the customer and avoid frustration and the urge to engage in creative self-service, resulting in the wrong item being picked.

Actions we can take to implement RFID against shrinkage

Always start with a pilot

Select one store or product category. Demonstrate the idea and compute the amount of shrinkage reduced specifically, and take that data to get wider investment.

Always tag a source

Collaborate with suppliers to tag items when manufacturing. This is the most effective procedure, and this guarantees full coverage of the tags on the first day only.

Try to integrate

Have your RFID software all integrated with your current Inventory Management System (IMS), Point-of-Sale (POS), and loss prevention systems. Data silos murder effectiveness.

Communication is the key

Be open with employees. RFID positioning as a means of enhancing efficiency and product availability, and not as a policing tool only. Educate them about its advantages so as to lower the resistance internally.

Manage your defense

RFID is most effective when used in a layered security solution. Add to that, employee training, a clear audit trail, data analytics, and ethical leadership will make it a holistic anti-shrinkage culture.

The RFID automated inventory transforms the loss prevention department, which is dynamic and operated on a guesswork basis to an active, data-driven unit. It minimizes the possibility of being robbed; the veil of invisibility that criminals count on is destroyed, and the expensive human mistakes are eliminated logically. The outcome is the direct quantifiable bottom-line enhancement, a conversion of the accepted cost of business into a controlled and manageable variable.

In a world where margins are narrow and competition is stiff, it is no longer a luxury to be able to have every single asset secured; it has become a necessity. That is made possible by RFID, the silent sentinel, who makes it happen, through one single accurate, real-time scan.

FAQ

What makes RFID tech different from barcode technology?

RFID identifies tags with radio waves that are not line of sight. In comparison to barcodes, packaging allows a reader to scan hundreds of items instantly, and the inventory counts are provided at a much faster and more precise rate.

How to use RFID to prevent theft?

It provides real-time visibility. Door and point readers can identify unpaid items going out of doors or any suspicious item movement, and are a great deterrent and quick investigation measure.

Can RFID only be used to prevent shoplifting?

No. It dramatically cuts down on administrative errors such as miscounts and shipment discrepancies, which are a leading cause of shrinkage. Machines receiving and counts of the cycles eradicate expensive human errors.

Is RFID technology expensive?

The expenses have been reduced to a considerable degree. Beginning with a pilot on high-shrinkage items will give a clear ROI, as this will eliminate loss. Supplier tagging can also be used to control start-up costs.

Should we replace all of our barcode systems?

Not necessarily. RFID is able to complement the current systems. Many businesses use both, and the RFID data is incorporated into the existing inventory programs to provide a more effective tracking, without a complete and immediate upgrade.