The lowly barcode has served the supply chain tracking for decades. It is stable, cheap, and universally accepted. But with the rise in e-commerce and the escalation in the need to find the accuracy of the day, optical scanning is proving to be blown out to a neck throb by the stringent demand.

The question of branding that warehouse managers are posing is: Is it time to upgrade? This guide not only goes beyond basic but also addresses the essential questions about the distinction in operationality between the RFID (Radio Frequency Identification) and the Barcode systems to enable you to make your choice on which technology will enable the future of your facility.

What is the fundamental difference between how RFID and Barcodes capture data?

This is because there was a variation in the communication mode: Optical vs. Radio.

Barcodes are Optical

A scanner would need to project the beam of light striking the printed code to scan a barcode. This requires a “line of sight.” The scanner is unable to read the barcode if it is on the bottom of a box, it is dirty, or it is positioned in the wrong direction. A man has to touch the box or the scanner in order to create the connection.

RFID is Radio-Based

RFID involves the use of radio waves in carrying out communication between a tag and a reader. This does not need the line of sight. The tag will be read as long as the reader is within their presence (20+ feet UHF RFID said to be readable). The reader is able to read labels inside closed boxes without having to open them because it is possible to see through cardboard, wood, and plastic.

How do the two technologies compare in terms of scanning speed and labor efficiency?

This is where RFID offers the greatest leap in its operations.

Barcode (The “One-by-One” Limit)

Barcode scanning is a sequential process. To scan Item A, a worker should scan Item B, and then scan Item C. Even when being a fast worker, one can scan only a few items with a maximum of 10-15 items/minute. This renders such activities as inventory cycle counts extremely time-consuming and taxing.

RFID (The “Bulk” Advantage)

RFID is capable of being used to do multiple things at once. A contemporary RFID reader has the capabilities of reading hundreds of tags simultaneously. An employee will be in a position to move along an aisle with the help of a handheld reader and scan hundreds of items in as little time as it takes to scan two barcodes.

Real-World Impact

The data provided by Zebra Technologies demonstrates the reduction of inventory cycle count times by RFID up to 90 percent. One team of four people can work a whole weekend to accomplish the job, which could be carried out by a single person within a couple of hours.

Which system offers better accuracy and data visibility?

Although barcodes can be read correctly on scanning, they are subject to human error since humans operate them.

The Use of Missed Scan:

Within the barcode system, when a worker loses track of an item and fails to scan it before loading it on a truck, the system will still assume that it is still within the warehouse. This generates inventory drift.

RFID identified Visibility:

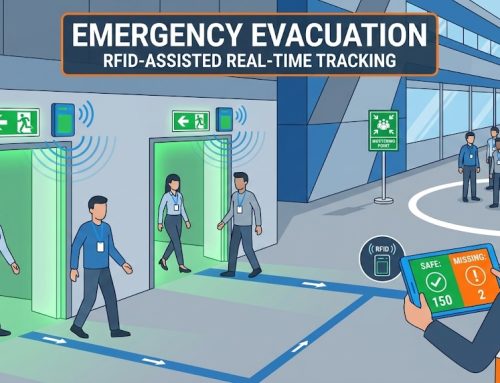

RFID allows passive tracking. The system can automatically track items by scanning them as they travel by having fixed readers in the dock doors or conveyor belts. No human trigger is needed. When a forklift pushes a pallet of 50 items through a dock door, the system will automatically update all 50 items as having been shipped.

This automation eliminates human error, which tends to make inventory accuracy go well above the industry average (65-70 percent) to 99 percent plus.

Isn’t RFID significantly more expensive than Barcodes?

Historically, yes. Nevertheless, the pricing has changed.

Consumables Cost

Fractions of a penny are the cost of a barcode label. RFID inlay is much more expensive (5-15 cents on average). In the case of low-value products (such as a pack of gum), the economical option is barcodes.

Total Cost of Ownership (TCO):

In high-value assets, cases, or pallets, the labor savings provided by RFID are frequently greater than the value of the tags. Impinj, a well-established firm in manufacturing RFID, points out that ROI is not the price of the tag, but rather the cost of getting rid of chargebacks, the compensation costs of fewer labor hours, and lost sales in case of out-of-stock.

Considering the expense of paying people to check items manually throughout the year, the less expensive barcode system is usually more costly to run.

Can these two technologies coexist, or must I choose one?

They almost always coexist. It seldom turns out to be an all-or-nothing decision.

A hybrid method is more likely to be used in most successful RFID implementations.

- RFID finds application in the internal inventory control, receiving, and shipping validation to achieve speed and accuracy.

- The barcodes are stored on labels in duplicate form and compatible format to partners that do not have RFID readers.

- The GS1 Standard: International standards bodies, such as GS1, encourage the utilization of RFID (EPC) and standard barcodes (GTIN) in order to have goods that can be traced across the various partners in the supply chain with ease, irrespective of their level of technology.

Conclusion

Barcodes will never leave the supply chain, yet when it comes to those businesses that desire to have speed, high accuracy, and automation, it is one of the legacies that present a legacy limitation.

RFID also makes the warehouse not a warehouse where individuals look, but an intelligent warehouse, and it will tell you the location of objects. It will change your expenditure on manual work to tactical automation.

FAQs

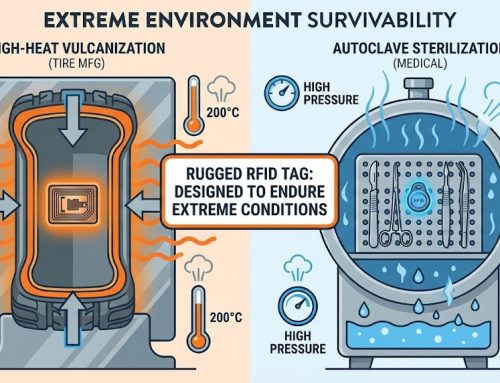

Is RFID reliable in environments with lots of metal or liquid?

RFID has been a challenge previously, as metal and liquid interfered with radio waves. This has, however, been addressed by the modern on-metal tags as well as the advanced interference-rejection algorithms. Although there is a need to do site calibration and tag selection carefully, RFID is currently being utilized to track metal kegs, liquid-filled drums, and heavy machinery with success.

Is switching to RFID a difficult integration for my IT team?

It does require middleware. An RFID reader cannot be simply inserted into a PC and be expected to work as a keyboard (like barcodes do). This requires software (such as the platform offered by Senitron) that will act between the readers and your WMS/ERP. This middleware selects the great river of data (removing duplicate reads) and transmits clean and actionable instructions to your primary system.

Do I need to replace my entire WMS (Warehouse Management System) to use RFID?

Generally, no. The majority of the modern RFID solutions are the ones that are meant to be an add-on or an edge solution. They are connected to your existing WMS (such as SAP, Oracle, or NetSuite) through API and could be fed with the data by a barcode scanner, thus it may appear to the WMS. You are updating your data capture system, and not removing the functioning brain.