RFID (Radio-Frequency Identification) is not a new coin in the logistics and retail industry, making it easier to manage inventory through a simple wave of a reader. But its greatest performance of perseverance occurs on the warehouse shelf.

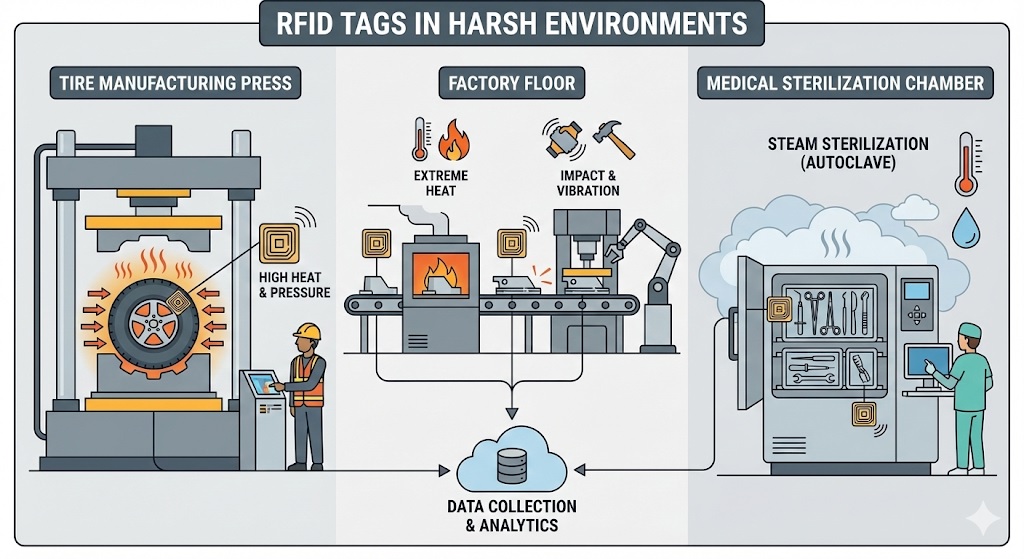

Suppose a little electronic device were not only still alive, but alive, and growing, in a tire mold at 200 °C and great pressure, or it were still alive, after being subjected, day after day, to the scathing, steamy wrath of a 121 °C sterilization autoclave. It is not science fiction, but this is how RFID is addressing the most important tracking difficulties in one of the most severe industrial conditions in the world.

What Do We Mean by Harsh Environment?

One has to go through the ordeal that these tags go through in order to appreciate the success.

Tire Vulcanization

This is the procedure by which a green tire is cured in the mold at very high pressure (usually 150 deg C to 200 deg C) and with extreme heat. This converts soft rubber into a high-performance material that is durable.

Any tag installed in it has to survive not only the thermal shock, but also the chemical environment, pressure capable of deforming metal, and eventually the daily flexing and stress of tires.

Sterilization

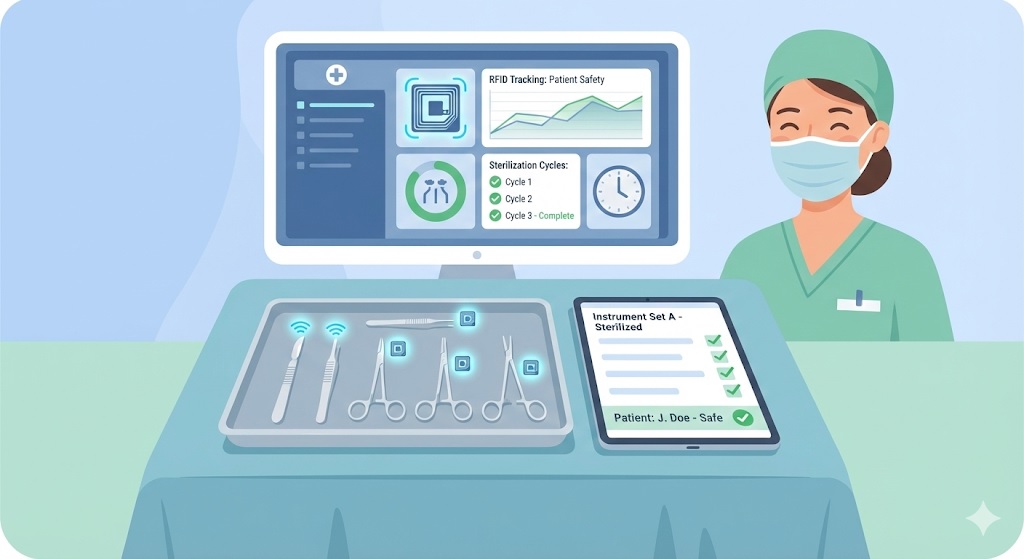

The safety of patients in hospitals is the most important thing. The tools used in surgery are carefully sterilized using steam in autoclaves, during which they are subjected to saturated steam at temperatures ranging between 121 °C (or even 134 °C) over prolonged periods.

This forms an ideal combination of high heat level, extreme moisture (100% humidity), and chemical corrosion caused by cleaning agents. There must be thousands of these cycles that a tag can endure without breaking or causing any contamination to the sterile field.

Such conditions would shred the standard RFID tags, QR codes, or barcodes in a jiffy. A special category of hardware called High-Temperature RFID Tags is the solution.

Technology Engineered for An Unbreakable Tag

Designing such applications in the form of tags is a task of material science and micro-engineering. The essence of the dilemma is to armour the silicon chip and its fragile aluminium antenna-elements, which by nature are highly intolerant of heat, moisture, and pressure.

Selecting the Material

The tag is packaged in materials that are selected due to their strength.

- Thermoplastics Such as PEEK or PI (Polyimide)

These are high-performance polymers, and the glass transition temperature is much higher than the heat of the application, which makes them solid and resist melting or deformation.

- Specialized Epoxies & Ceramics

Are used to pot or to cover the internal parts to give a hermetic seal to infiltrated moisture and chemical attacks.

- Stainless Steel Housings

In the most harsh conditions, the tag is laser-welded in a small, bio-compatible stainless steel capsule, forming an impervious fence.

Importance of Attachment

The only thing any tag can be is the bond between it and the asset.

In the case of tires, the tag is vulcanized into rubber during the curing process and can be located on the sidewall or under a rubber patch. The bonding has to be perfect to avoid air pockets or high-speed tag fly-out.

In the case of surgical instruments, tags are normally welded to a spot, clamped in place through a handle, or embedded on a ceramic data button. The connection should be able to resist the expansion/contraction of heat and should not interfere with the sterility of the tool or its operations.

The Data Lifeline

It is essential what is stored on these tags.

Unique Identification (UID): The tires or tools receive a globally unique serial number.

This inventory forms a record of permanent digital history that allows complete life cycle tracing of manufacture, through generations of sterilization or miles of road, to ultimate retirement.

Tips That Will Help in The Successful Implementation

Implementation of RFID in such extremes must be planned. Here are key tips for success:

Start with a Pilot

Do not implement a full-scale implementation the first time. Test a batch of tags using the real process (e.g., 50 tools with 100 sterilization cycles, or a pilot batch of tires) and confirm that data integrity and physical survival rates are valid.

Importance of the Reader Placement

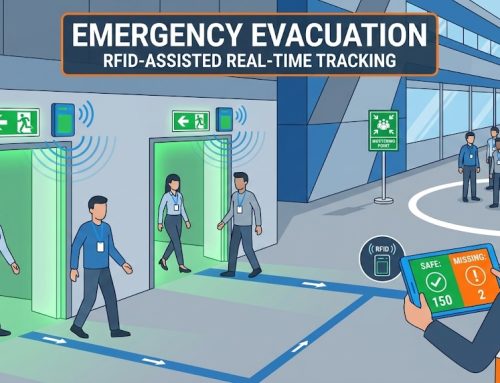

Secure your RFID readers and antennas in antagonistic industrial locations. Install sturdy, IP67 enclosures and put them in places not subjected to direct heat sources or steam jets. Look at the possibility of incorporating readers into the autoclave doors or even the vulcanization press platens to scan automatically.

Choosing the Right Frequency

The tires have UHF (Ultra-High Frequency) tags that have a greater range of reading when used in warehouses or within the production line.

HF (High Frequency, 13.56 MHz) tags, typically employed on tools, are not so easily affected by interferences caused by metals and liquids–so frequent in surgical sets and autoclaves.

Integrate

The real value is uncovered when RFID data enters your core systems. Make sure that your tags and readers are able to integrate with:

Enterprise Resource Planning (ERP)

Manufacturing Execution Systems (MES).

Central sterile supply department (CSSD) software.

Focus on the Process

It is 30 percent technology and 70 percent change in the process to succeed. Train new scanning processes on staff. Rebuild workflow carts and trays to aid reading. Act on the information to create proactive insights, such as preventive maintenance when tools are about to reach their cycle limits.

Learn About the Payoffs

Investment in these ruggedized systems returns the transformative returns:

- Do away with missing tools or tire moulds that are not accounted for.

- Record sterilization cycles automatically and use them in audit trails.

- Schedule surgical equipment according to the real data of the cycle, rather than an assumption.

- It is not difficult to clone a barcode, but close to impossible to imitate a single, factory-inserted RFID tag.

- Do away with manual counting and errors in counting in sterilization departments and tire inventory.

Extreme environment RFID is the highest level of technology usage. It goes beyond mere identification to be one of the building blocks of safety, quality, and intelligence in manufacturing and healthcare. These small forged sentinels of defining extreme conditions allow us to have a crystal clear peek into processes hitherto black boxes and make extreme conditions opportunities to achieve unprecedented control and trust.

FAQ

What is important for an RFID tag to survive extreme heat?

The chip and antenna are covered by special materials such as PEEK plastic, ceramics, or laser-welded stainless steel housings. It is the materials with very high melting points, and they provide a hermetic seal against moisture and pressure.

Where to place a tag on your car tire?

The tag is vulcanized into the rubber itself in the manufacture process, and is usually underneath a protection patch of rubber or embedded into the sidewall. This makes sure it becomes permanent and lasting in the structure of the tire.

Can tracking surgical tools improve patient safety?

It offers a smart, error-free audit trail. The system ensures that all the tools are adequately sterilized according to the number of cycles required, and the tools are indicated as being in need of maintenance or retirement, thus removing any guesswork.

Can we use the same RFID tags for both tires and surgical tools?

Not usually. Although both are high-temperature tags, they are designed in a different manner. The tags on surgical tools tend to operate with HF frequency and require biocompatible steel casings. Tire tags are normally UHF, and they are designed to attach to rubber.

What are the biggest benefits of using RFID in harsh conditions?

It allows 100 percent automated traceability. This converts processes that are critical yet opaque (such as curing or sterilizing) into transparent and data-supported operations, which guarantee safety, quality, and compliance throughout the production process to end-use.